1. Introduction: The Importance of Packaging in the Medical Industry

1.1 Strict Requirements for Packaging in the Medical Industry

In the medical industry, product packaging is not just for aesthetics or ease of transportation. The main task of packaging is to protect the product and ensure its safety during transportation, storage and use. Medical equipment and devices often require particularly delicate packaging to prevent any interference from external factors, such as pollution, moisture, ultraviolet rays, etc., which may affect the quality and effect of the product. Therefore, the materials and designs of medical packaging must meet strict international and regional standards to ensure that the product is always in the best condition before use.

For medical device manufacturers, choosing the right packaging material is particularly critical. It is not only related to the shelf life and reliability of the product, but also to the safety of consumers. Whether it is surgical instruments, consumables, or other medical supplies, they must go through a strict packaging process to ensure that they are sterile when used and will not be damaged by external factors.

1.2 The impact of the selection of packaging materials on the medical industry

With the advancement of technology and the rapid development of the medical device industry, the selection of packaging materials is no longer a simple technical requirement. It also involves regulatory requirements, environmental standards, production efficiency and other aspects. For example, some traditional packaging materials (such as plastic and wood pulp paper) not only provide protection functions, but also bring environmental problems. For this reason, more and more companies are beginning to seek more environmentally friendly and efficient packaging solutions, which is also an important reason why Blue Film Roll For Medical Device Packaging has become a popular choice.

In addition, with the acceleration of globalization, cross-border transportation of medical products has become more frequent. Packaging must not only provide sufficient protection functions, but also meet the regulatory requirements of different countries. This puts higher demands on the adaptability and reliability of medical packaging materials, and Blue Film Roll just meets this.

2. Application of Blue Film Roll in Medical Device Packaging

2.1 What is Blue Film Roll?

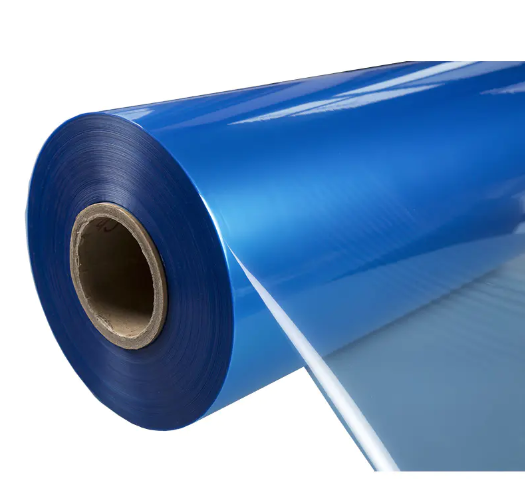

Blue Film Roll refers to a special film material that is usually used for the packaging of medical devices and equipment. This blue film is treated with PP or PE coating to provide additional strength and protection. Unlike traditional packaging materials, Blue Film Roll has a high degree of transparency and flexibility, which can clearly display the contents of the package and ensure convenient operation and packaging while maintaining structural strength.

Blue Film Roll is not only suitable for standard packaging needs, but can also be customized according to customer requirements to meet the packaging needs of different types of medical devices. Its material and coating give it a stronger protective function, which can effectively prevent factors such as pollution, moisture, and mechanical damage from affecting the product.

2.2 How does Blue Film Roll meet the needs of medical packaging?

Blue Film Roll has gradually become the preferred material for medical device packaging due to its excellent performance. First of all, Blue Film Roll has high tear strength, which can effectively prevent packaging damage during handling and transportation. Secondly, the PP/PE coating gives it excellent moisture resistance, which can ensure the long-term storage of products in a humid environment. In addition, the antibacterial properties of Blue Film Roll are also particularly outstanding, which helps to prevent the growth of microorganisms and ensure the safety of medical devices.

Most importantly, Blue Film Roll can provide complete closure and effectively block external pollution and environmental factors. For some high-precision medical devices, such as surgical instruments, any external contamination may lead to serious consequences. Therefore, the integrity and safety of medical packaging are particularly important, and Blue Film Roll stands out in this regard with its strong protective performance.

2.3 Improve packaging efficiency

Another major advantage of Blue Film Roll is its ease of processing. Due to its softness and plasticity, Blue Film Roll can easily adapt to automated packaging systems. In modern medical device production, automated production lines place higher demands on packaging efficiency. Blue Film Roll can meet these demands, improving overall production efficiency by increasing packaging speed and reducing labor costs.

Compared with traditional packaging materials, Blue Film Roll has significant advantages in processing speed and automation, reducing the consumption of human resources while improving the accuracy and consistency of packaging.

3. Environmentally friendly characteristics of Blue Film Roll

3.1 Trend of environmentally friendly packaging

With the improvement of global environmental awareness, more and more industries have begun to pay attention to the environmental protection of product packaging. The medical industry is no exception, especially in the context of strict regulations and increasing consumer environmental awareness, the demand for environmentally friendly packaging materials has increased dramatically. Although traditional plastic packaging can provide good protection, its negative impact on the environment is obvious. Therefore, the medical industry needs to seek sustainable packaging solutions to meet the dual needs of environmental protection and economy.

In order to promote the development of the green medical industry, many manufacturers have begun to choose packaging materials that can be recycled and degraded, which can not only meet the basic functions of packaging, but also reduce the burden on the environment.

3.2 Environmental advantages of Blue Film Roll

As an environmentally friendly material, Blue Film Roll has strong recyclability and degradability. This gives it a significant environmental advantage in the packaging of the medical industry. Compared with traditional plastic packaging materials, Blue Film Roll can reduce resource consumption during the production process and can be recycled and reused after use. In this way, it reduces dependence on non-renewable resources such as oil and reduces the carbon footprint of the product.

In addition, during the production process of Blue Film Roll, the emission of waste and harmful substances can be reduced by optimizing the process, effectively reducing pollution to the environment. With the increasingly stringent environmental regulations, choosing this environmentally friendly packaging material can not only help companies reduce operating costs, but also help enhance the company's social responsibility image and win recognition from consumers and the market.

4. Technical advantages of Blue Film Roll

4.1 Excellent physical properties

The material of Blue Film Roll is usually made of high-density polyethylene or polypropylene, which have excellent physical properties in themselves. They are both strong and flexible and can withstand the impact of the external environment. At the same time, Blue Film Roll also has the characteristics of UV resistance and chemical corrosion resistance, which enables it to maintain its integrity in various complex environments. Whether it is exposed to sunlight for a long time or encountered chemical corrosion, Blue Film Roll can effectively protect medical devices from damage.

4.2 Easy to process and customize

Blue Film Roll has strong adaptability during the processing process and can be customized according to the size and shape of different medical devices. This means that Blue Film Roll can not only meet the standardized packaging needs, but also be customized according to the requirements of specific medical devices, providing tailor-made packaging solutions for different products.

In addition, Blue Film Roll is very convenient during the processing process. It can be seamlessly connected with automated packaging equipment and can also be used efficiently in manual operation. This enables Blue Film Roll to play an important role in all aspects of medical device production and ensure the efficiency and accuracy of the packaging process.

4.3 High adaptability: suitable for different types of medical devices

Medical devices are of various types, ranging from small precision instruments to large surgical equipment, and the required packaging materials are different. With its high adaptability, Blue Film Roll can meet the packaging needs of various types of medical devices. It is not only suitable for small-volume, regular-shaped medical products, but also can provide reliable protection for equipment with complex shapes and extremely high precision requirements.

This diverse adaptability makes Blue Film Roll unparalleled in the field of medical packaging. Whether it is daily consumables or high-end medical equipment, Blue Film Roll can provide high-quality packaging solutions.

5. The prospects of Blue Film Roll in the global medical packaging market

5.1 The growth of the global medical device market drives packaging demand

With the acceleration of global population aging and the advancement of medical technology, the medical device industry is growing at an astonishing rate. This has brought unprecedented opportunities and challenges to the medical packaging industry. The growth of medical devices has directly driven the increase in packaging demand, and Blue Film Roll has gradually become a key player in this market with its unique advantages.

With the increase in global medical demand, Blue Film Roll will become one of the most popular packaging materials on the market, especially in developed countries and emerging markets, where its demand will continue to grow.

5.2 Regulations and standards in the medical industry drive the development of packaging materials

The packaging materials in the medical industry must not only meet the needs of product protection, but also comply with strict regulations and standards. Medical packaging regulations around the world are constantly being strengthened, and higher requirements are being placed on the environmental protection, safety, functionality, etc. of packaging materials. As a packaging material that meets these requirements, Blue Film Roll is expected to be more and more widely used in the global market, especially in those regions with high requirements for packaging standards.

6. Market acceptance and competitiveness of Blue Film Roll

6.1 Views and evaluations of experts in the industry

Industry experts generally believe that Blue Film Roll has extremely high technical content and market potential. Its high performance and environmental protection characteristics make it a future trend in the medical packaging industry. Experts believe that the demand for environmentally friendly and safe packaging is increasing worldwide, and Blue Film Roll will be the main choice for packaging in the medical industry in the future.

6.2 Competitive advantages and market development

Compared with other traditional packaging materials, Blue Film Roll is able to occupy a place in the market with its comprehensive performance advantages. It not only has the characteristics of protection, environmental protection and high adaptability, but also can improve packaging efficiency while reducing production costs, which makes it stand out in the fiercely competitive market.

In the future, with the continuous advancement of technology and the continuous increase in market demand, Blue Film Roll is expected to become the mainstream material for medical industry packaging and win the favor of more companies.

7. Conclusion: The Future of Blue Film Roll for Medical Device Packaging

7.1 Continuous Innovation and Industry Development

With the continuous development of the medical device industry, the technological innovation of packaging materials is also continuously advancing. As a new type of packaging material, Blue Film Roll has broad market prospects. With the increasing demand for high-performance and environmentally friendly packaging materials, Blue Film Roll will continue to play an important role in the future.

7.2 The important role of Blue Film Roll in the future medical industry

With the continuous improvement of the medical industry's requirements for packaging materials, Blue Film Roll will become an important part of future medical device packaging. By continuously improving its performance and technology, Blue Film Roll will help the medical industry better cope with increasingly severe challenges and provide safer and more environmentally friendly packaging solutions.

+86 139-6715-0258

+86 139-6715-0258

Monday to Friday 8 am. to 6 pm.

Monday to Friday 8 am. to 6 pm.

English

English 中文简体

中文简体