With the rapid advancement of technology, electronic products are everywhere in our lives. At the same time, the problem of static electricity has gradually become a challenge that cannot be ignored. During the manufacturing, storage and transportation of electronic products, static electricity may cause serious consequences, such as damage to electronic components, system failure and even fire. In this context, Antistatic Film has become an important tool for electrostatic protection.

1. Basic principles of Antistatic Film

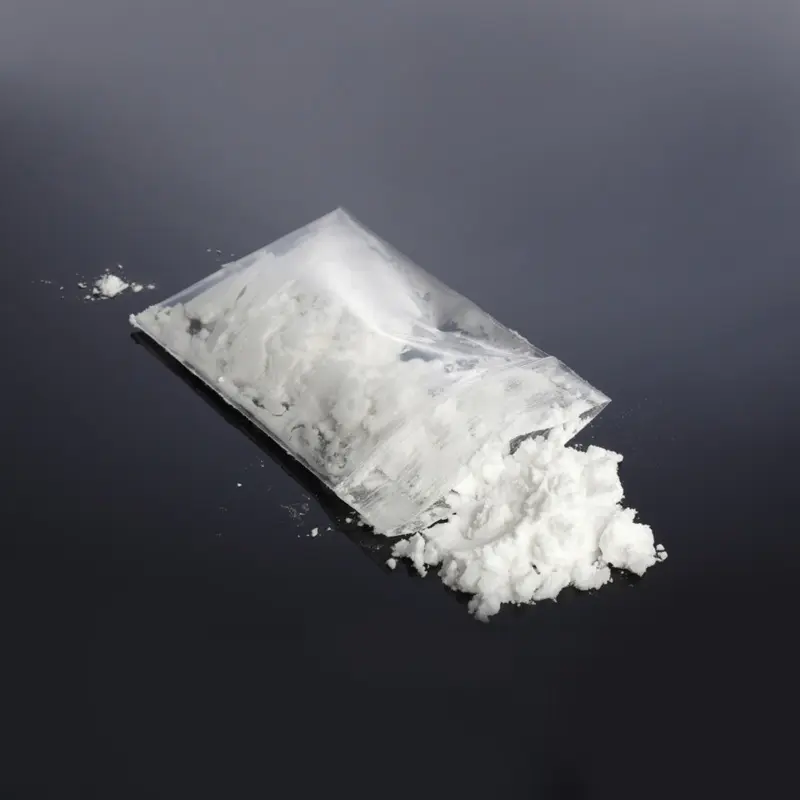

Antistatic Film is a material with antistatic function. Its main principle is to make the material have a certain conductivity by adding specific conductive substances on the surface or inside the material, thereby effectively preventing the accumulation and discharge of static electricity. This conductive substance can be metal, metal oxide, conductive polymer, etc., which can form a tiny conductive network, allowing charges to flow freely on or within the material surface, thereby avoiding the accumulation of static electricity.

2. The main functions of Antistatic Film

Prevent the accumulation of static electricity: One of the main functions of Antistatic Film is to prevent the accumulation of static electricity. In the manufacturing process of electronic products, static electricity is easily generated due to the influence of various factors (such as friction, contact, separation, etc.). If static electricity cannot be dissipated in time, charge accumulation will form on the surface of the object, causing a series of problems. Antistatic Film, through its conductivity, can effectively conduct charges away from the surface of objects and avoid the accumulation of static electricity.

Reduce electrostatic discharge: Electrostatic discharge refers to the process of charge flowing from a high potential area to a low potential area, usually accompanied by sparks and electric shocks. This discharge process may not only damage electronic components, but may also cause serious consequences such as fire. Antistatic Film can effectively reduce the risk of electrostatic discharge by quickly exporting charges through its conductive network to prevent charges from accumulating on the surface of objects to a sufficient extent to trigger discharges.

Protect electronic components: During the manufacturing, storage and transportation of electronic products, electronic components are often the most susceptible to static damage. Antistatic Film can effectively protect electronic components from static electricity. By covering the surface of electronic components with Antistatic Film or using it as packaging material, you can effectively prevent static electricity from damaging electronic components and improve the reliability and stability of electronic products.

Improve production efficiency: In the manufacturing process of electronic products, static electricity problems often lead to production line pauses and increased maintenance costs. By using Antistatic Film, you can effectively reduce the incidence of static electricity problems, reduce the pause time of the production line, and improve production efficiency. At the same time, Antistatic Film can also reduce the damage rate of electronic components, reduce maintenance costs, and further improve the economic benefits of the enterprise.

3. Application fields of Antistatic Film

Antistatic Film is widely used in various situations where static electricity accumulation and discharge need to be prevented, such as electronic product manufacturing, semiconductor production, medical device manufacturing, chemical industry, etc. In these fields, Antistatic Film plays a vital role, providing a strong guarantee for product quality and safety.

Antistatic Film, as a material with antistatic function, plays an important role in preventing static electricity accumulation and discharge, protecting electronic components, and improving production efficiency. With the continuous development of science and technology, the application fields of Antistatic Film will become more and more extensive, and its position in the field of electrostatic protection will become more and more important.

+86 139-6715-0258

+86 139-6715-0258

Monday to Friday 8 am. to 6 pm.

Monday to Friday 8 am. to 6 pm.

English

English 中文简体

中文简体