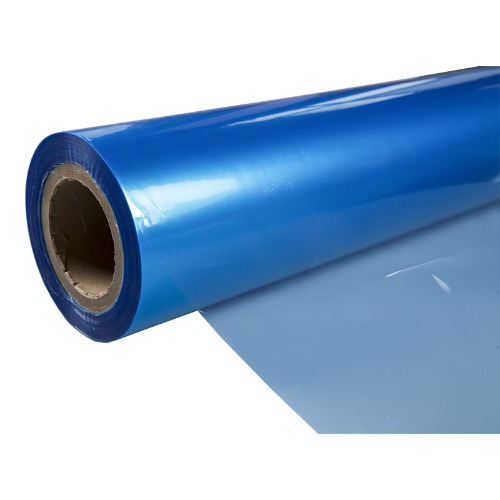

The Crucial Role of Blue Film in Medical Device Packaging

In the complex and highly regulated world of medical device manufacturing, packaging is far more than just a container. It serves as the ultimate safeguard, the first and last line of defense for patient safety and the sterility of medical consumables. Among the myriad of available materials, the blue film roll is a conspicuously prevalent choice. This distinctive color is no mere aesthetic whim; it’s a meticulously calculated design choice rooted in scientific principles. The vibrant blue provides a stark contrast against the white of medical-grade paper, a feature of paramount importance in paper-plastic pouch packaging. This high-contrast pairing allows healthcare professionals to instantly and clearly spot any minute tears, punctures, or compromises in the package’s integrity upon opening. Such immediate visual feedback is critical, preventing the use of potentially contaminated medical instruments and thereby enhancing safety in clinical settings. Furthermore, this specific color facilitates seamless automated optical inspection on production lines, significantly boosting the efficiency and accuracy of quality control processes.

Beyond Protection: Unveiling the “Secret Weapon” of PE/PET Materials

The unique demands of medical packaging necessitate materials that possess exceptional performance and can withstand a battery of rigorous tests. PE (Polyethylene) and PET (Polyethylene Terephthalate) are two primary materials for medical packaging films, and their widespread adoption is no accident. They are the “secret weapon” that guarantees the sterile environment for medical devices, thanks to their outstanding physical properties and chemical stability. PE imparts superior heat-seal capabilities to the film, enabling it to form a robust, secure seal with medical-grade paper that effectively blocks bacteria and contaminants. Its flexibility and puncture resistance also provide crucial physical protection for the enclosed devices. PET, on the other hand, is renowned for its exceptional transparency, mechanical strength, and high-temperature resistance. When these two materials are combined through co-extrusion technology, they create a synergistic composite film that leverages the best of both worlds: excellent heat-sealability from PE and high strength and clarity from PET. This composite film offers bespoke protection for medical devices of all shapes and sizes.

The Sterile Path: Navigating the Challenges of Ethylene Oxide and Gamma Ray Sterilization

Following packaging, medical devices must undergo stringent sterilization before they can be used. Common sterilization methods include Ethylene Oxide (EO) sterilization and Gamma Ray (radiation) sterilization. These processes place extremely high demands on the packaging materials. EO sterilization requires the film to have excellent breathability, allowing the gas to penetrate the package while still acting as an effective microbial barrier. The film must also maintain its structural integrity without deforming or degrading during the sterilization cycle. Gamma ray sterilization is even more demanding. It uses high-energy radiation to kill microorganisms, a process that generates a large number of free radicals that can cause ordinary plastics to become brittle, discolored, or suffer a decline in physical performance. Medical-grade PE/PET films are specially formulated and processed to effectively resist radiation-induced degradation, preserving the material’s flexibility and strength. This ensures the package retains its reliable sterile barrier function even after sterilization.

Innovative Synergy: The Perfect Partner for Paper-Plastic Packaging

In the realm of medical device packaging, paper-plastic pouches represent a classic and highly effective combination. The pairing of blue film with medical-grade paper is not a simple physical layering; it is a perfect functional complement. The paper provides superior breathability and microbial filtration, making it an ideal medium for the penetration of EO gas during sterilization. The blue film, meanwhile, serves as a physical barrier against water and moisture and enhances the overall mechanical strength of the package. When these two materials are securely joined through heat-sealing, they form a sterile barrier system that allows sterilization gases to pass through while effectively blocking the ingress of external contaminants. A particularly clever design feature of this type of packaging is the sterile peel opening. With precise control over the peel strength, healthcare professionals can easily and cleanly peel the film away from the paper without generating particulate matter, thereby preventing secondary contamination and ensuring the device remains sterile during retrieval.

A Guide to Selection: How to Evaluate the Right Medical Packaging Film

Navigating the vast market of packaging materials to select the right medical packaging film is a decision of paramount importance. This choice goes beyond mere cost considerations; it is a matter of responsibility for product safety and patient health. First, it is crucial to have a deep understanding of the characteristics of the medical device being packaged, including its shape, weight, sterilization method, and anticipated storage conditions. This will help determine the appropriate film type (PE, PET, or a composite) and thickness. Second, a focus on the film’s physical performance metrics—such as tensile strength, puncture resistance, heat-seal strength, and peel strength—is essential. These properties ensure the film can meet the demands of automated packaging lines, as well as the protective requirements during transportation and storage. Finally, it is imperative to confirm that the film supplier’s products comply with international and domestic medical device packaging standards and can provide complete quality certifications and traceability documents. A rigorous evaluation and selection process is the cornerstone of safe and reliable medical device packaging.

+86 139-6715-0258

+86 139-6715-0258

Monday to Friday 8 am. to 6 pm.

Monday to Friday 8 am. to 6 pm.

English

English 中文简体

中文简体