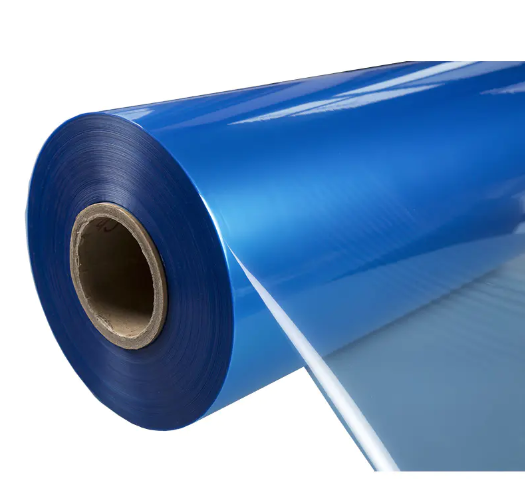

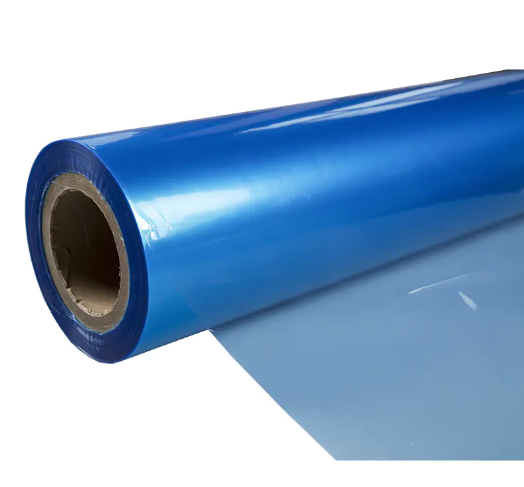

Industrial Standards: Wholesale Heavy Duty Stretch Wrap Film Roll for Pallets

In the global supply chain, the structural integrity of a shipment is only as strong as its containment method. Selecting a wholesale heavy duty stretch wrap film roll for pallets is a strategic decision that directly impacts loss prevention and operational safety. High-performance films must exert consistent restorative forces to keep heavy or irregular loads from shifting during the high-vibration environment of sea or road transit. As an innovative enterprise established in 2003, Hangzhou Zhongcheng Material Technology Co., Ltd. has dedicated over two decades to the research and development of plastic films, ensuring that industrial users receive products capable of withstanding extreme mechanical stress. With a registered capital of 100 million yuan and a robust quality assurance system, the production of these films involves rigorous testing methods to verify tensile strength and tear resistance. Our 15,000 square meter factory base in Hangzhou is equipped with advanced technology to produce films that serve as the gold standard for heavy-duty applications. By utilizing specialized resins and multi-layer extrusion, we provide high-performance solutions that safeguard everything from construction materials to industrial machinery, ensuring that every pallet remains a secure, unified load regardless of the journey's complexity. This level of reliability is essential for large-scale distributors who cannot afford the financial and reputational costs of damaged inventory.

- Maximum load retention for heavy freight ensures workplace safety during unloading.

- Advanced resin blends provide superior puncture resistance against sharp crate edges.

- High-yield rolls reduce the frequency of roll changes, increasing warehouse throughput.

- Multi-layer technology allows for thinner films with higher containment force.

| Feature | Standard Stretch Film | Heavy Duty Industrial Film |

| Film Thickness (Gauge) | 12 - 17 Microns | 20 - 30+ Microns |

| Puncture Resistance | Moderate | Excellent / Reinforced |

| Load Capacity | Light to Medium | Heavy / Irregular / Industrial |

Tactical Selection: Clear vs Black Stretch Wrap Film Roll for Moving

When preparing inventory for relocation or storage, choosing between clear vs black stretch wrap film roll for moving involves balancing operational visibility with security needs. Clear film is the preferred choice for general logistics as it allows personnel to easily identify products, read barcodes, and check for signs of damage without unwrapping the pallet. However, in high-security environments or for high-value retail goods, black film provides a vital layer of privacy, concealing the contents from unauthorized eyes and deterring "theft by attraction." Beyond security, specialized black films produced at our Hangzhou headquarters often include UV inhibitors, protecting sensitive materials from degradation when staged in outdoor sun-exposed areas. Our 15-acre production base and 25-story R&D center, representing a 500-million-yuan investment, drive continuous innovation in these specialty films. Whether you require transparency for inventory tracking or opacity for cargo security, the material technology ensures that the film maintains its cling and elastic memory across diverse environmental temperatures. This versatility makes the choice between clear and black films a tactical decision based on the specific risks and requirements of the move.

- Clear film facilitates rapid inventory audits and barcode scanning.

- Black film conceals high-value items to prevent tampering and theft.

- Opaque colors help in color-coding shipments for different regional destinations.

- UV-stabilized black films protect goods stored in outdoor environments.

| Criteria | Clear Stretch Film | Black Opaque Film |

| Visual Verification | High (Barcode Friendly) | Low (Content Concealed) |

| Security Level | Standard | High (Anti-Theft) |

| UV Protection | Limited | Excellent (With Additives) |

Operational Efficiency: Industrial Hand Stretch Wrap Film Roll with Handles

Manual wrapping stations often suffer from worker fatigue and inconsistent tension, which can be mitigated by using an industrial hand stretch wrap film roll with handles. Ergonomic design is at the heart of modern packaging efficiency; by integrating handles or extended cores, operators can apply film with a natural grip, reducing the risk of friction burns and back strain. Since our inception in 2003, we have focused on providing thoughtful pre-sales technical support to help clients optimize their manual wrapping processes. A well-applied stretch wrap film roll prevents product "toppling" during local delivery, where frequent starts and stops occur. Our team of more than 100 employees works within a reliable quality assurance system to ensure that hand-grade rolls unwind smoothly and provide the necessary "tack" to secure the load at the first layer. Improving the ergonomics of the packaging line not only protects the health of the workforce but also ensures that every pallet is wrapped with the correct tension, minimizing the amount of film used per load and reducing overall material costs.

- Integrated handles improve operator speed and reduce manual effort.

- Extended cores allow for easier wrapping of the bottom of the pallet.

- Consistent tension application leads to fewer product damages during transit.

- Lightweight roll specifications prevent long-term physical strain on warehouse staff.

| Efficiency Metric | Standard Hand Roll | Hand Roll with Handles |

| Operator Fatigue | High | Low |

| Application Speed | Moderate | Fast |

| Tension Consistency | Variable | High |

The Green Shift: Sustainable Recycled Stretch Wrap Film Roll Suppliers

As the industry moves toward a circular economy, the demand for sustainable recycled stretch wrap film roll suppliers has reached a critical point. Innovative companies are now integrating Post-Consumer Recycled (PCR) content into their film formulations without compromising the essential properties of stretch and clarity. At Hangzhou Zhongcheng Material Technology Co., Ltd., our 500-million-yuan investment in the Zhongcheng Building R&D center symbolizes our commitment to sustainable material science. We focus on developing high-performance films that reduce environmental impact while maintaining the reliability required for industrial use. Sustainable films are no longer a niche product; they are a requirement for global corporations striving to meet Corporate Social Responsibility (CSR) and ESG goals. By choosing recycled alternatives, businesses can significantly reduce their plastic footprint while benefiting from the advanced technology and production equipment used in our 15,000 square meter factory. Comparing performance reveals that modern recycled films can match the tensile strength of virgin resin films, provided they are manufactured under a rigorous quality assurance system.

- PCR integration helps businesses comply with emerging environmental regulations.

- Bio-based additives are being researched to improve the degradability of films.

- Downgauging technology allows for less plastic use while maintaining load stability.

- Recycled content films support the green branding initiatives of modern enterprises.

| Sustainability Factor | Virgin Resin Film | Recycled PCR Film |

| Carbon Footprint | High | Significantly Lower |

| Material Source | Petroleum-based | Post-Consumer Waste |

| Tensile Strength | Standard Baseline | Comparable (95-100%) |

Precision Engineering: High Performance Machine Stretch Wrap Film Roll Specifications

For high-volume automated packaging lines, understanding high performance machine stretch wrap film roll specifications is vital for cost-per-pallet optimization. Machine-grade films are engineered to be pre-stretched by automated turntables or orbital wrappers up to 300% before application. This extreme elongation requires a film with zero defects and high puncture resistance to avoid costly line stoppages. Our production facility utilizes advanced testing methods to ensure that every machine roll delivers consistent performance. A stretch wrap film roll designed for machine use features specific "cling" properties, typically one-sided, to prevent pallets from sticking together during the loading and unloading of trucks. By focusing on high-performance specifications, facilities can maximize their throughput and minimize film waste, achieving a significant return on investment through material savings. With our headquarters in the Binjiang District of Hangzhou, we remain at the forefront of material technology, providing the technical support needed to calibrate machinery for the best possible film performance.

- Pre-stretch capability of 250-300% reduces the total amount of film per pallet.

- High-speed machine compatibility ensures zero-breakage at peak production.

- Consistent gauge control prevents uneven tension and load failure.

- High-clarity finish allows for easy scanning of internal inventory.

| Machine Spec | Standard Machine Film | High Performance Film |

| Pre-stretch Ratio | 150% - 200% | 250% - 300%+ |

| Tear Strength | Standard | Enhanced / Multi-Layer |

| Application Speed | Moderate | High-Speed Automated |

FAQ

How does film gauge affect pallet security for heavy industrial goods?

The gauge, or thickness, of a stretch wrap film roll is a primary factor in the containment force it exerts. For heavy industrial goods, a higher gauge (typically 80 gauge or 20 microns and above) is necessary to provide the "muscle" required to keep heavy items from shifting. However, with modern multi-layer technology, some high-performance thinner films can provide equal containment force to thicker traditional films. Choosing the correct gauge prevents load shifting and ensures that the film does not snap under the weight of the cargo.

Can recycled stretch film be used in food-grade or medical environments?

While sustainable recycled stretch wrap film roll suppliers are making great strides, the use of recycled content in direct food-contact or medical applications depends on the source of the PCR and the specific certifications of the manufacturer. Most recycled films are currently used for secondary packaging (wrapping boxes on a pallet) rather than primary packaging. For direct food or medical contact, specialized virgin resins or highly refined recycled materials with FDA-equivalent approvals are required to ensure zero contamination.

What is the optimal storage temperature for maintaining film cling?

Maintaining the performance of your stretch wrap film roll requires proper storage. The optimal temperature is generally between 15C and 25C in a dry environment. Extreme heat can cause the film's "cling" additives to migrate or degrade, making the film too sticky or lose its tack altogether. Conversely, extreme cold can make the film brittle and prone to breaking during the stretching process. Proper storage ensures that the technical specifications of the film remain consistent until the moment of application.

What is the difference between cast and blown stretch film?

Cast film is produced by feeding resin through a slot die and over chilled rollers; it is known for its high clarity, quiet unwind, and excellent cling. Blown film is produced by blowing a large bubble of molten resin and then collapsing it; it is much tougher, has higher puncture resistance, and is louder during unwind. For heavy-duty industrial applications with sharp corners, blown film is often preferred, while cast film is the standard for high-volume, quiet warehouse environments.

+86 139-6715-0258

+86 139-6715-0258

Monday to Friday 8 am. to 6 pm.

Monday to Friday 8 am. to 6 pm.

English

English 中文简体

中文简体