In the global heavy-duty logistics sector, load containment is the most critical factor in preventing product damage and ensuring transport safety. A stretch wrap roll for packing is no longer viewed merely as a secondary packaging material; it is an engineered structural component designed to hold multi-ton pallet loads together under extreme dynamic forces. Achieving the optimal balance between film tension, elasticity, and material consumption requires a deep understanding of polymer rheology and the latest international shipping standards.

The Physics of Containment: Measuring Force and Tension

Load containment is defined by the "holding force" exerted by the film on the cargo. While manual application is common for low-volume operations, it often results in inconsistent tension. Integrating a machine grade stretch wrap roll for packing automation allows facilities to achieve a high pre-stretch ratio, often exceeding 250-300%, which maximizes the film's elastic memory. According to the latest 2024-2025 technical updates to the EUMOS 40509 standard, dynamic safety testing now mandates specific containment force thresholds at the top, middle, and bottom of the pallet to prevent "load tilting" during emergency braking.

Source: EUMOS - European Safe Logistics Association Load Rigidity Standards

While manual wrapping depends on operator strength and often leads to loose loads, automated machine wrapping provides a uniform, high-tension wrap that significantly reduces material usage per pallet.

| Application Method | Average Pre-Stretch Ratio | Containment Consistency | Film Waste Percentage |

| Manual Wrapping | 50% - 100% | Low (Subjective) | High (>20%) |

| Machine Grade Stretch Wrap | 250% - 350% | Extreme (Programmable) | Minimal (<5%) |

Structural Resilience: Puncture Resistance and Edge Protection

Industrial loads often feature irregular geometries that can easily compromise film integrity. Sourcing a puncture resistant stretch wrap roll for packing sharp edges is essential when dealing with metal components, crated machinery, or masonry products. Blown film technology typically offers superior multi-directional tear resistance compared to cast film, though recent advancements in nano-layer extrusion have enabled cast films to reach similar levels of toughness while maintaining high clarity.

Standard films often fail at the corners of sharp objects, leading to total load unraveling, whereas high-performance puncture-resistant films distribute the stress across the polymer chain to maintain structural containment.

| Material Property | Standard Utility Film | Puncture Resistant Film |

| Dart Drop Impact (g) | < 150g | > 350g |

| Tear Resistance | Linear (High Propagation) | Cross-linked (Low Propagation) |

| Edge Failure Risk | High | Very Low |

Optical and Operational Efficiency: Visibility and Noise Control

Logistics efficiency is not just about strength; it is also about scanability and the working environment. For high-value goods, utilizing a high clarity stretch wrap roll for packing electronics allows for rapid barcoding and RFID scanning without removing the protective layer. Furthermore, the acoustic environment of a warehouse is improved by using a silent release stretch wrap roll for packing in warehouses. Traditional films produce high-decibel "chatter" during unwinding, which can lead to worker fatigue and reduced safety awareness.

According to the 2025 OSHA Occupational Noise Exposure report, reducing ambient noise in high-volume packing zones by just 10 decibels significantly improves operator concentration and long-term auditory health.

Source: OSHA - Occupational Noise Exposure Standards and Research

Economic Strategy: Optimizing Cost per Pallet

Procurement departments often focus on the wholesale stretch wrap roll for packing prices 2026 as a primary metric. However, the true ROI is found in the "cost per pallet wrapped." High-performance films with superior pre-stretch capabilities allow for a thinner gauge to be used while achieving higher containment force, effectively reducing the total weight of plastic used per shipment.

Although the initial price per roll of high-performance film is higher than that of economy-grade film, the total cost per pallet is lower because significantly less film is required to reach safety standards.

| Cost Metric | Economy 80 Gauge Film | High-Performance Pre-Stretch Film |

| Grams of Film Per Pallet | 450g - 600g | 200g - 300g |

| Total Containment Force | Moderate | High / Certified |

| Relative ROI | Low (High Waste) | Very High (Eco-Efficient) |

About Our Manufacturing Excellence

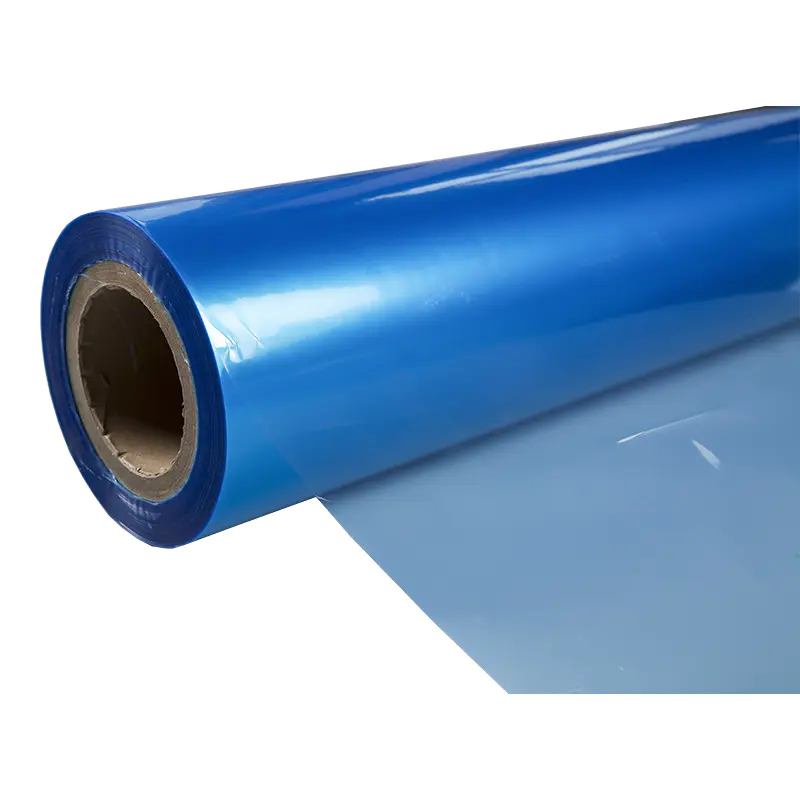

Our company stands as a pioneer in the production of advanced polymer solutions for the global logistics market. We specialize in the manufacturing of the stretch wrap roll for packing, utilizing 5-layer and 7-layer co-extrusion technology to ensure maximum stretchability and puncture resistance. Our commitment to engineering excellence means our products are compatible with the latest automated packing systems, helping our B2B partners meet both safety regulations and sustainability goals through reduced material consumption and superior load stability.

Frequently Asked Questions (FAQ)

1. How do I choose between cast and blown stretch wrap?

Cast film is generally preferred for a silent release stretch wrap roll for packing in warehouses due to its quiet unwind and high clarity. Blown film is typically chosen for extreme puncture resistant stretch wrap roll for packing sharp edges in industrial settings.

2. Will high clarity wrap affect barcode scanning?

No, using a high clarity stretch wrap roll for packing electronics actually improves scanning efficiency. The superior optical properties prevent laser diffraction, allowing handheld scanners to read barcodes through multiple layers of film.

3. What are the wholesale price trends for 2026?

The wholesale stretch wrap roll for packing prices 2026 are influenced by resin costs and the demand for thinner, high-performance materials. Investing in higher-quality films usually results in a 15-20% reduction in total annual spend due to decreased material volume.

4. Can machine-grade film be used for hand wrapping?

While possible, it is not recommended. A machine grade stretch wrap roll for packing automation requires high tension to activate its elastic properties. Hand wrapping cannot reach the 200%+ stretch required to make the film cost-effective.

5. Does high-performance film help with sustainability?

Yes. By using advanced resins that allow for "down-gauging" (using thinner film for the same strength), you significantly reduce the amount of plastic waste sent to landfills per pallet shipped.

+86 139-6715-0258

+86 139-6715-0258

Monday to Friday 8 am. to 6 pm.

Monday to Friday 8 am. to 6 pm.

English

English 中文简体

中文简体